By 2030, service management will look totally different. With tech moving fast, customers wanting things quicker, and OEMs teaming up in smarter ways, everything about how service works is changing. Businesses are relooking at how they operate, and staying ahead now means using AI, automation, better data, and mobile tools that just make life easier.

Automotive service and OEMs are coming together, linking up things like scheduling, repairs, warranty info, and customer chats. Let’s check out what the future holds for service management systems, the major service management trends, what it all means, what could go wrong, and how to handle it. We’ll also see how NetFlows360 helps companies make these changes without a hitch, making things clearer and boosting productivity and customer happiness.

Major Service Management Trends OEMs Should Watch in 2026

1. AI & Data Analysis

AI is going to be a big deal in service management. It’ll handle tasks on its own and use data to guess when things need fixing, decide who does what, and make better decisions.

For OEMs, data smarts will help guess what’s coming, avoid running out of parts, and cut down on downtime. AI dashboards will give quick insights, warning managers about problems, which makes customers happier and boosts productivity.

Examples- Predicting repairs for cars and workshops

- Using AI to put service requests in order

- mart workflow ideas for OEMs’ networks

- If we depend too much on AI, we might lose some of that human touch.

- Collecting tons of data brings up privacy worries.

- Have people double-check important decisions.

- Stick to strict data rules that follow GDPR, CCPA, and industry standards.

2. More Automation

Automation connects AI, RPA, workflow management, and decision-making to run things on its own. For cloud service management and OEM software, this means quicker request handling, automatic job cards, real-time updates, and correct billing across networks.

More automation makes workflows faster and strengthens the overall service management system across the dealer network.

Examples- Automatic claims and warranty approvals

- Service scheduling that works with inventory management

- Getting resources and people to work together

- Combining tech can be pricey.

- Automation might mean some people lose their jobs or need new skills.

- Plan to roll things out slowly with test runs.

- Train workers for new roles, like data analysis or AI supervision.

3. Better Language Processing (NLP)

NLP will change how people use the automotive service management software module, making tasks faster and more conversational. OEMs will use AI to enter data, ask for updates, and manage workflows by talking. Voice commands, chatbots, and language options will make interacting with the service system feel natural.

Examples- Technicians asking about parts by voice

- Chatbots giving repair updates

- AI for global OEMs operations

- NLP might not understand what you’re saying.

- Voice control could let unauthorised people in.

- Keep NLP models updated with different data.

- Use passwords and access levels for security.

4. AR & VR

AR and VR can change service by making training, diagnostics, and support better. AR can guide technicians, while VR can copy repairs for training, which cuts down on mistakes and speeds up resolution.

Examples- Remote support with AR guidance

- VR training for technicians on new cars

- Simulations for warranty claims

- Equipment and software can cost a lot.

- Staff might have trouble with new tech.

- Start with specific uses.

- Offer training for employees.

5. Blockchain for Security

Blockchain gives a safe way to record service histories, warranty claims, and approvals. For OEMs, it makes sure service records can be traced, which stops fraud and makes audits better.

Examples- Secure tracking of claims and invoices

- Sharing records across dealers

- Confirming OEMs’ parts and services

- Technical problems and slow performance

- Unclear rules in new areas

- Test blockchain in controlled settings.

- Follow the rules and keep an eye on regulations.

6. Data Analysis

Analytics will make DMS better by giving performance data, trends, and resource use. Analytics can spot problems, guess what’s going to happen, and suggest how to make service network performance better.

Examples- Predicting busy times for service centres

- Finding dealers who need help

- Tracking spare parts inventory

- Too much data could be overwhelming

- Data bias could mess up analytics

- Create a data management system.

- Make sure you have different data sources for insights.

7. IoT

IoT sensors in cars and equipment will allow maintenance, diagnostics, and support. When it works with DMS, teams can respond to problems, which cuts down on downtime and costs.

Examples- Remote automotive monitoring

- Alerts for maintenance

- Inventory based on equipment use

- Cybersecurity risks for connected devices

- Managing data at scale

- Encrypt IoT communications

- Use data systems to manage IoT data

8. Cybersecurity

As cloud services become key to networks, cybersecurity is super important. These capabilities ensure that the entire service management system stays secure and compliant.

Examples- Monitoring who’s accessing the platform

- Threat data in dealer dashboards

- Automatic system updates

- Cyber threats are always changing

- Putting security in place costs money

- Keep monitoring and updating things

- Set aside resources for security

9. Edge Computing

Edge computing handles data nearby, which cuts down on delays and improves insights. For OEMs’ networks, this means quicker diagnostics, AI decisions, and workshop operations.

What Could Go Wrong- Setting up the infrastructure costs a lot

- Handling things in different places raises security issues

- Use edge computing for key tasks

- Use security on the devices themselves

10. Sustainability

Keeping an eye on the impacts of IT and service will be important. From efficient data centres to fleet routing, sustainability will help companies stand out.

What Could Go Wrong- It costs a lot to put in place

- It’s hard to measure the impact

- Focus on things that give you a return on investment

- Use standard reporting

11. Unified Experience

A smooth experience across devices is going to be key for productivity. Employees, customers, and partners will use the same interface.

What Could Go Wrong- Technical problems with old systems

- People might not want to change

- Roll things out slowly and get feedback

- Offer training

12. Employee Experience

Service systems will track how well employees are doing and how they’re feeling. This makes things more efficient and reduces turnover.

What Could Go Wrong- Privacy issues

- Getting data to work together

- Be transparent and get consent

- Work with HR and IT

13. Support

Solutions will guess what you need and fix problems early. This builds trust and reduces complaints.

What Could Go Wrong- False alarms

- Customers might not believe it

- Fine-tune the models

- Explain the benefits and limits

14. Computing

Quantum computing will allow quick solutions. OEMs’ networks could use insights for maintenance, make supply chains better, and run simulations.

What Could Go Wrong- The tech is still new

- It costs a lot

- Join pilot programs

- Share expertise and costs

NetFlows360: Making Service Easier, Improving How Things Run

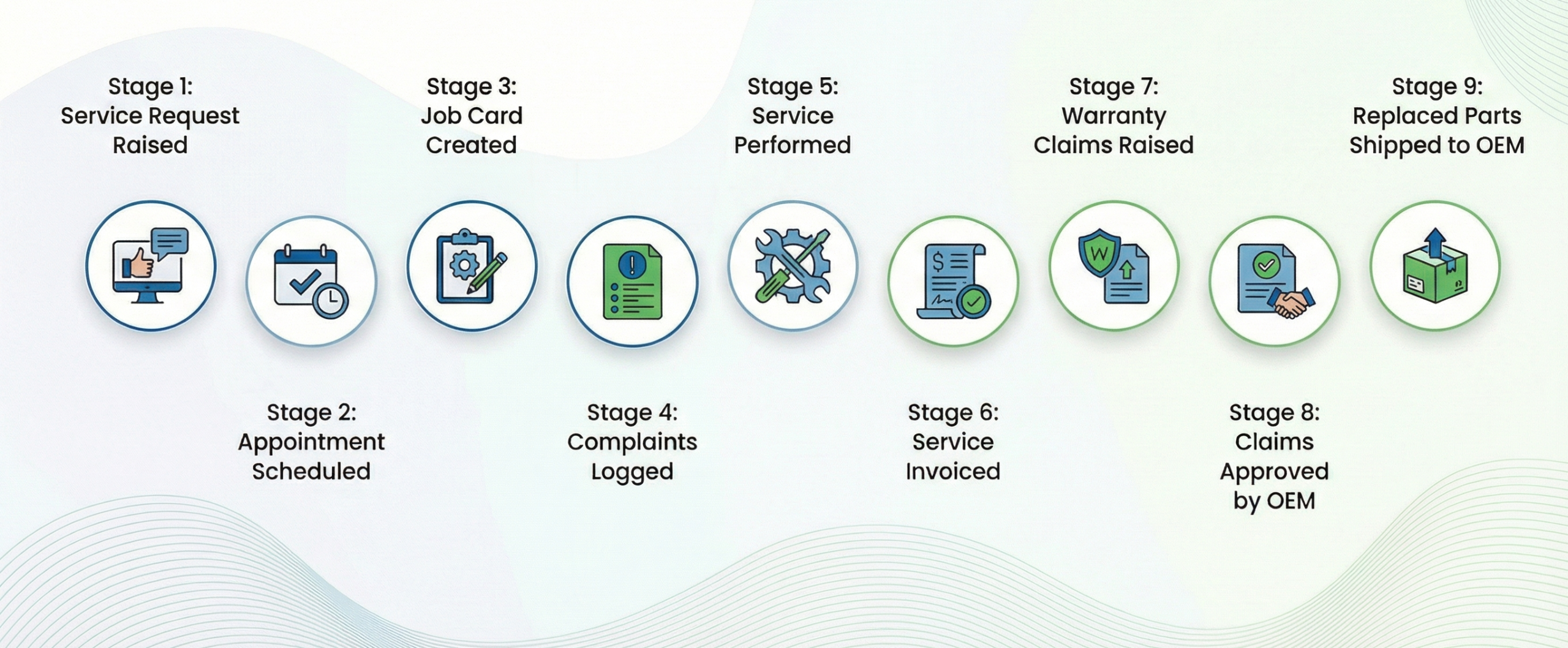

Service management is changing fast, and NetFlows360 is keeping up. We make it easier to manage service across networks for OEMs. We put everything together on one platform and hook up ways for customers to talk to you. This means things run better, you get better info, and customers are happier.

1. Service Management All in One Place

Keep an eye on all your service appointments, job cards, bills, and warranty stuff across your dealer network. You can see everything clearly and have better control.

2. Easy Appointment Scheduling and Follow-Ups

Set up service appointments, send out automatic reminders, and get dealer workshops organised to save time. Fewer delays, fewer repeat visits, and happy customers.

3. Simple Job Card Handling

Make and keep track of job cards that have all the important stuff, like services done, who worked on it, and what parts were used. You’ll know exactly what’s going on with each service job.

4. Easy Way to Track Complaints and Fixes

Take care of customer complaints, get things where they need to be, and follow repairs from start to finish. Reports show what happened with every service thing, so everyone knows what’s up.

5. Invoices, Warranties, and Claims Sorted

Make correct invoices, handle warranties, and follow claims as they go through. This keeps things flowing smoothly through the dealer network.

In Conclusion

Service management should get smarter and more hooked up by 2030. Things like robots doing work, machines thinking, and the internet connecting devices should make things go faster and make service better for everyone.

Getting this tech in might cause some trouble, like keeping things safe and getting teams ready. Companies that see this coming and try new stuff will probably do well.

NetFlows360 shows what a modern service management system can be. It puts things in one place, lets you see info as it happens, and betters many parts of OEM management software for a smooth, easy-to-use service thing.

FAQs

In the next ten years, service management will probably use robots to do work, data to figure things out, and the internet to connect devices.

Cloud platforms keep data together, show info as it happens, let you use it on your phone, and help everyone work together in the dealer networks.

Customers want more, and new ideas like fixing things before they break are making changes in the automotive service management software module.

Future service management software module will watch data, give ideas, have robots do tasks, help with phone use, and keep everyone responsible in dealer networks.